Parker Velcon

Filtration Division

Parker Velcon

Clean Diesel Filtration

Parker Velcon Aviation Fuel Handling

Parker Velcon are a leading manufacturer of filtration in the aviation industry, fabricating hundreds of different filter cartridges, with a range of filtration efficiencies in a variety of configurations to meet specific industry standards. This includes a complete line of cartridges qualified to the latest editions of EI specifications (EI 1581, EI 1583 & EI 1590).

The three main filter vessels in the aviation industry are as follows:

Filter Water Separators

Filter water separators are two-stage vessels designed to remove dirt and

separate water from fuel at refineries, product terminals, fuel farms

and on refuelling vehicles.

They continuously coalesce and separate water, which collects in the

vessel sump where it can be drained. Parker Velcon Filter water separators have

passed numerous tests qualifying them to the latest EI 1581 edition.

Construction is to ASME Code. Units qualified to military specifications

are also available.

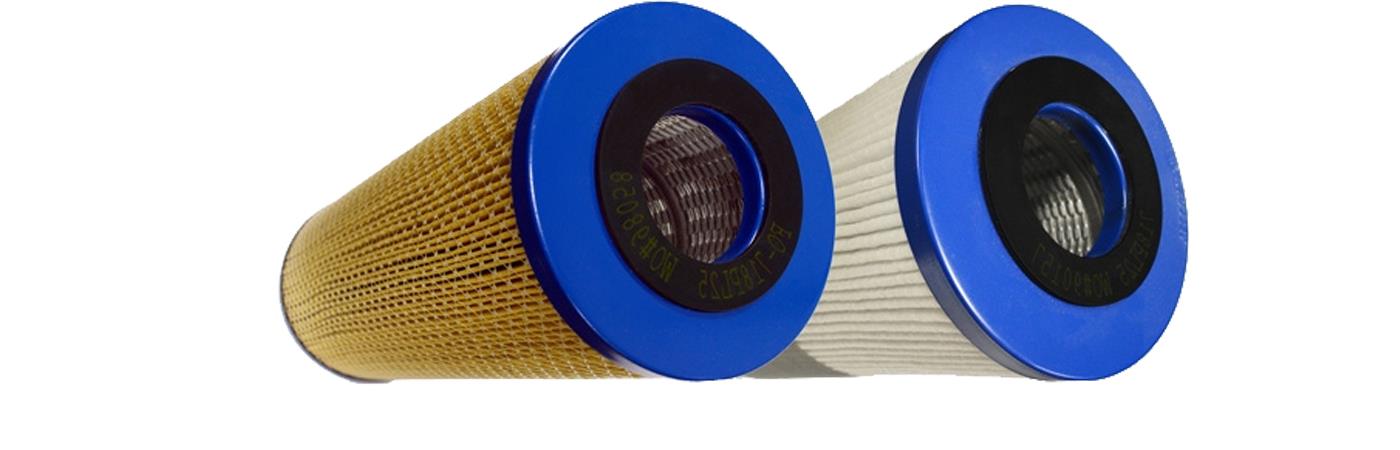

Filter Water Separator Elements

Filter Water Separator Elements

Filter Monitors

Filter monitors are single stage vessels designed to remove dirt and separate water from Avgas and Jet Fuel and provide protection from water at the point of final fuel filtration. When a monitor system’s water holding capacity is reached, the flow of

fuel is restricted. Units meet all EI Specifications. Construction is to ASME Code Section VIII.

Monitor Element

Monitor Element

Micronic and Clay Vessels

Micronic and Clay Vessels remove dirt and surfactants. Micronic

vessels offer economical particulate prefiltration upstream of clay

units or Filter/Separators. Clay elements remove surfactants.

Construction is to ASME Code Section VIII.

Micro Filter Elements

Micro Filter Elements

Clay Elements

Clay Elements

Diesel filtration vessels manufactured to meet stringent downstream ISO 4406, ASTM D975 and EN 590:2009 cleanliness standards for both diesel and biodiesel fuels.

Velcon Clean Diesel

Velcon Clean Diesel